Building Paintings

To carry out the project

Safe method of access

Conform to safety at work

Quality paint supply

Experience manpower

Meet deadline of work

Insurance security

Improve and rectify wall defects

Method Statement

Painting Works

Safety & Health Requirements

Painting Procedure

Access Method

Site Preparation

Application Of Painting

Access Method

ROPE ACCESS/ABSEILING

SKYLIFT

GONDOLA

SCAFFOLDING

ACCESS PLATFORM

Paint Related Problems & Remedy

Problem : Is a crusty white salt deposits.

Effective Treatment – Waterproofing on outside wall.

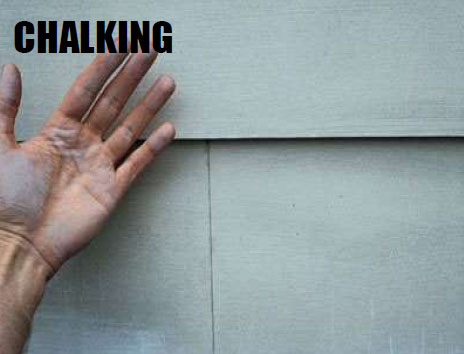

Problem : Is a powdery surface due to poor binding effect.

Effective Treatment – Thorough wash with high pressure machine and apply solvent primer prior repainting.

Problem : Fungus

Effective Treatment – To apply anti-fungus solution prior painting.

Problem: Paint cracks on wood siding and trims.

Effective Treatment – To remove old flakes and seal thoroughly all surface with appropriate primer before repainting.

Type of Paint For Surface

External Wall Surface

- Alkaline Resisting Primer

- Weather Resistant Exterior 100% Acrylic Paint/Waterproof Membrane Paint/Silicone Paint/Solvent Paint

Internal Wall Surface

- Internal Emulsion Sealer

- Internal Acrylic Emulsion Paint/Solvent Paint

Roof Tile Surface

- Fungus Resisting Primer

- Heat Reflective & Anti Algae Protection Paint

Metal / Wood Surface

- Rust resistance undercoat

- Semi Gloss / Gloss Enamel Paint